Used

Sandvik DT 922i, 2016

€220 000

Year: 2016

Hours: 194

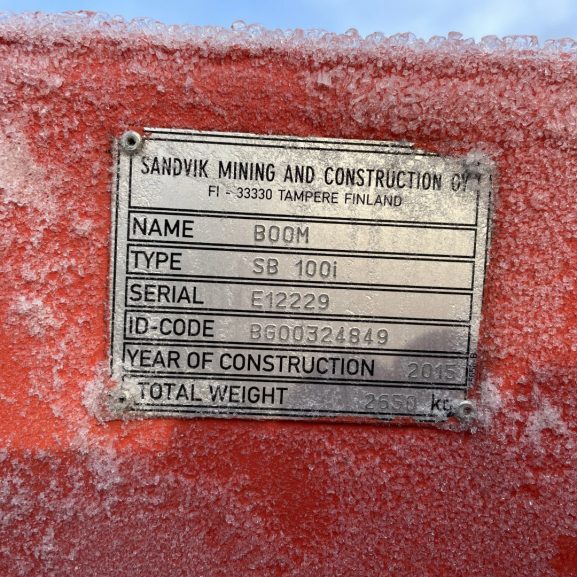

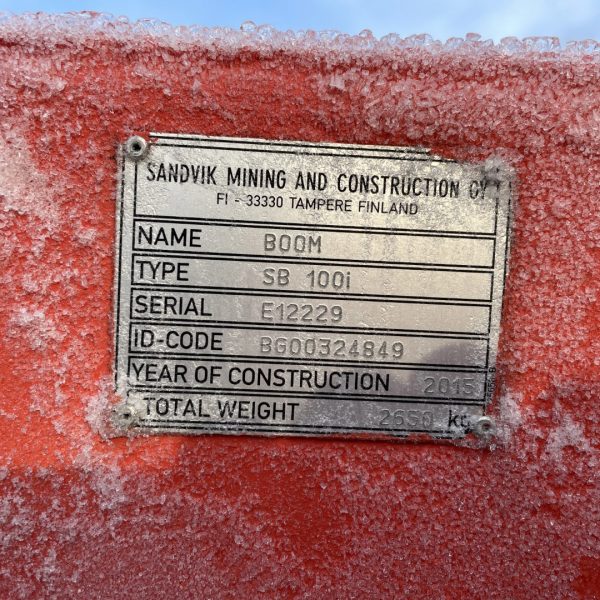

Beam 1: 2589 Impact hours

Beam 2: 2602 Impact hours

Ref nr: 16139

Description

Sandvik DT 922i

Year: 2016

Hours: 194

Beam 1: 2589 Impact hours

Beam 2: 2602 Impact hours

Compressor hours: 4963

Ref nr: 16139

Rock drills: 2 x RD525

Engine: Cummins QSB 6.7

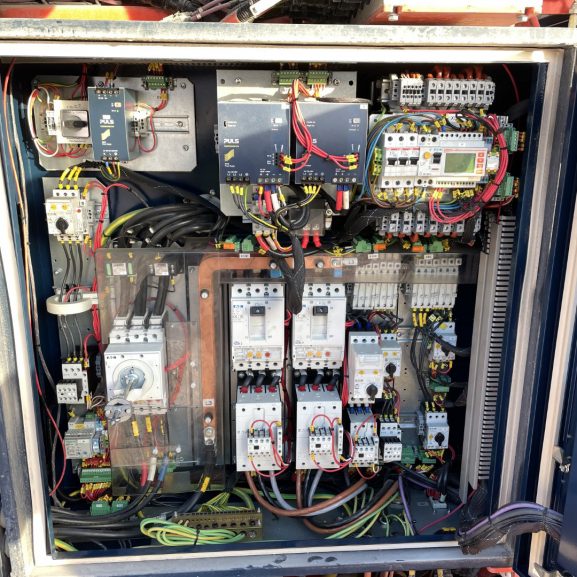

1000V/50Hz/190kW.

Been Served regularly by Sandvik

Extra Equipment

– CT28 air compressor instead of CTN10

– End-of-hole air flushing (including CT28)

– Water hose reel THR2.5E and 65 m (Ø38 mm) hose

– Hydraulic cabin elevation system

– Engine Cummins QSB6.7 (205 kW Tier4F) with WBP2HP water pump

– Automatic greasing system for carrier and booms (2-boom)

– Bypass hydraulic oil filter

– High pressure (180 bar) cleaning system with reel (TS 5-2120-B)

– Indicator light for jacks (up/down)

– Manual greasing unit with pump, reel and nozzle (TS 5-2110)

– Rod rack (max load 400 kg) on carrier side

– Vacuum pump for hydraulic oil

– Electric cable PUR (3×50 + 3×10) length 150 m

– 1000 V electric system and Direct-On-Line (DOL) starter (2-boom)

– 110 V or 230 V (16 A) outlet on carrier

– Dewatering pump outlet (max. 8 kW with transformer, 400 V)

– Remote joystick controlled spot lights (2 pcs)

– Access protector (mandatory in Europe with automated drilling)

– Spare hand held fire extinguisher 7.7 kg (Europe) or 9 kg (type ABC)

– Automatic fire supression system DAFO/FORREX

– Tramming cameras (rear, side and front)

– Data transfer (WLAN) including remote GUI view

– Drilling automation package: Platinum (DT922i)

– iSURE III Analysis

– iSURE II Report